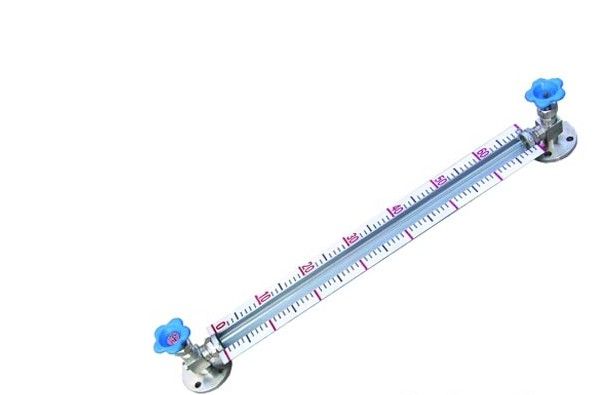

HG5 glass tube level gauge

The characteristics of the glass tube liquidometer:

The upper and lower valves are fitted with flange connectors, which form a connecting vessel with the container, which is directed by the glass tube to indicate the level of the liquid in the container. In from top to bottom in a steel ball valve, when the accident broken glass, steel ball under the action of internal pressure in the container automatically seal block channel, to prevent the containers within the medium to drain. The instrument upper end needle valve has limited plug screw, can be used for air, and the lower end needle valve also has a limited plug screw, which can be emptied, sampled, polluted and cleaned. The discharge valve shall be installed in the lower end for sample, repair, flushing or discharge. At present some small tube type level gauge also belong to the glass tube liquid level, the external material of stainless steel 304 (minimum) production, can use water, hydraulic oil, engine oil, etc. The use of 316 stainless steel is applied to the more corrosive medium.

Contents of glass tube liquidometer:

In transport, handling and installation, do not hit or hit, in case the glass pipe and glass are broken.

After installation, when the temperature is high, do not open the valve immediately, should warm 20 to 30 minutes, wait for the glass tube to have a certain temperature, then slowly open the valve. Valve open procedure: slowly open up the valve, then slowly open the valve, so that the medium is slowly entered into the glass tube.

In the use, wash the dirt of the inside and outside of the tube regularly to keep the liquid level clear. Cleaning procedures: first, close connection of the upper and lower valve, open the drain valve, put the net residual liquid inside the glass tube, using the appropriate cleaning agent or use the long pole ShuaLa MAO wipe method, clean up dirt tube wall.

4, if the quartz tube rupture or hang dirty when serious need to be replaced, the specific steps: remove the table body, unscrew nuts and nut on both ends, with a wooden stick to knock, quartz glass tube from one end to the other end out graphite ring, the new quartz tube into, then graphite ring set on the quartz tube, isometric embedding table body, tighten the nut and nut on both ends, after confirm no leakage, can be put into operation.

Glass tube level gauge structure:

Instrument G3 are fitted on the upper and lower valve / 4 "or the nipple M27 x 1.5, through flange connected to the container constitute connectors, through the glass tube container can directly show the height of the liquid level.

Instrument in fluctuation in all equipped with ball valve, when the glass tube because of the accident was broken, the steel ball inside the container pressure under the action of blocking, such container automatically closed, can prevent the liquid to drain from the container.

The valve of the instrument is equipped with a blocking screw, which can be used when sampling, or when the residue in the instrument is released during repair.