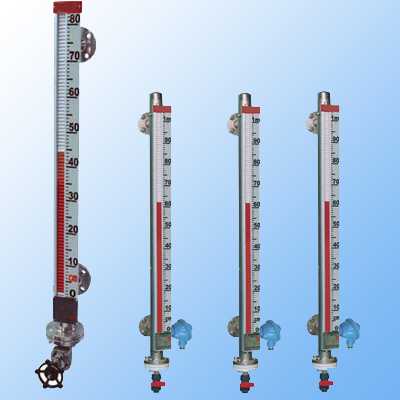

Working principle of magnetic flap liquid level gauge is the use of magnetic coupling effect, use measure the inspcetion lumen in the process of lifting magnetic double column for function of panel display liquid level, but sometimes we will find the real vats of liquid height is not corresponding with the Numbers on the front panel shown, what reason is this? In order to detect reasons, we will be up and down side of magnetic level gauge with turning tanks connected a flange on the valve closed, at this time will find sink float, through this article we together to get to know what is the specific reasons for such failure phenomenon, produce this kind of phenomenon, how can we solve correctly.

A magnetic flap, the first kind of circumstance is the level in the inspcetion stuck, inspcetion always sinking would happen, this is also so magnetic flap liquidometer fault the most frequently encountered situation;

Second, the inspcetion is one of the magnetic flap is an important part of the liquid level meter, float is a magnetic, display board have level, float is magnetic, this can be ruled out. Float sinking, the most likely reason is the density parameter supply is not accurate.

We speak magnetic float level gauge turning measuring principle is to use the principle of buoyancy, made a minimum level according to the medium density can float float, can with liquid level rise, the float will rise. The inner diameter of the stainless steel tube under the flap corresponds to the outside diameter of the float, and the outer diameter of the float is based on the density of the medium and the pressure of the medium. The main reason for the general measurement is the above two types, so the first rule excludes both cases.

The method of measuring the deviation of the deflection of the magnetic flip plate

Our magnetic magnetic level gauge turning in daily use process, often appear a now, that is magnetic level gauge measurement deviation, turning while the deviation is not very, but affect our practical application, then let me introduce you to a solution to the magnetic flap level gauge measurement deviation.

After the long term use of the rolling plate liquidometer, this body will have the sediment of the medium, which will affect the normal work of the float, and it must be cleaned regularly. Before cleaning, turn off the gas liquid phase valve and remove the residual material from the tube. After cleaning, assemble the original, the float is cut upside down, the seal mat should be replaced to prevent ageing leakage and tighten the screw. Magnetic flip gauge installation and use:

After installation, should first use the adjustment magnet steel to move slowly along the surface of the board, making all the red side of the board facing the observer.

2, the product must be installed vertically, the maximum deviation 3 ° or less

No ferromagnetism is allowed in the 200mm range of the liquid surface

This product is more than 4 meters, and must be added during the installation process

Before the liquidometer enters the operation, it should open the upper valve and slowly open the lower valve, allowing the medium to slowly flow into the cylinder, causing the flap to turn the tracking instructions one by one. Adjust the zero level with adjusting screw.

Before testing the container for pressure test, close the connection valve with the liquid level.

In the course of use, adjustment of the magnetic steel shall be adjusted for the failure of the individual tipboard due to the sudden change of the liquid level or other causes.