Transparent glass plate level gauge

One, the instrument's brief introduction:

Pervious to light type glass level gauge can be used to directly indicates the liquid level height in sealed container, has the structure is simple, intuitive and reliable, durable wait for an advantage, but in a container must be with steel, vulcanized fiber and graphite which do not corrode pressure ring.Under the liquid level meter is mainly composed of valve, valve, table, glass plate, plate, drain valve etc. Several major components.After improvement, liquid level gauge can no longer add other valves on both ends of the import and export, can remove the intermediate indicator for cleaning, keep furnace can add drain valve at the bottom of the liquid level gauge, in order to flush and drain in a timely manner.

Second, the working principle:

Pervious to light type glass level gauge is designed based on the principle of communicating vessels, made of glass and liquid level gauge body fluid pathway is over with the flange or taper pipe threads connected to the measured container connectors, observed through a glass plate surface and the container liquid level of the same level.Type level gauge on both ends of the needle valve not only ACTS as cut-off valve, its internal steel ball has the function of check valve leakage accident broken occurs when the liquid level meter, steel ball can be in medium pressure automatically closed fluid channel, to prevent from the enormous outflow liquid security protection.The level of material or change the parts to add some auxiliary parts can achieve anticorrosive, heat preservation, prevent the frost, lighting, and other functions.

Third, scope of application:

Pervious to light type glass level gauge advanced production technology, complete testing equipment, product structure is simple, installation, maintenance convenience, not blocked, no leakage, good drainage performance.The products are widely used in petroleum, chemical, electric power, metallurgy, medicine and other fields, can be directly to all kinds of high, the low pressure seal container or open storage tank of liquid level.

Four, unique advantages:

1, clear liquid level display, intuitive, can realize steam red liquid green double color display;

2, 360 ° range can be arbitrary adjust visual direction (in the low voltage type);

3, the types of products, more complete, has pervious to light type and reflection type, heating type, frost prevention type, no blind area type, double color type, prevent ultraviolet lines, wide liquid chamber type, lighting type, type of high temperature, high pressure and high temperature and high pressure type to choose from;

4, sealing structure is reasonable, no leakage;

5, on, under the valve is fast cut off protection device, safe and reliable;

6, with vent plug and drain valve.

Five, the performance indicators:

1, pressure rating: 2.5, 4.0, 6.3, 10.0, 16.0, 20.0, 25.0 MPa

2, the operating temperature: - 196 ℃ ~ 400 ℃

3, the standard center distance: 500800110, 0140, 0170 mm (can be produced according to user requirements)

4, standard visual range: 255550845114, 0143, 5 mm (can be produced according to user requirements)

5, heating steam pressure: 0.6 MPa or less

6, heating jacketed interface: within 1/2 "NPT thread

7, the valve automatically closed pressure: 0.3 MPa or less

8, connecting flange standards: HG20592 ~ 20635-97-3/4 "(flange standard, diameter, pressure and type of sealing surface differ according to user requirements production)

9, threaded connection interface: G3/4 "external thread

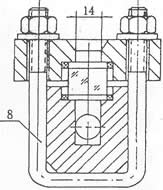

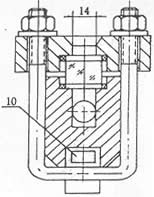

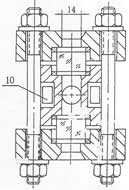

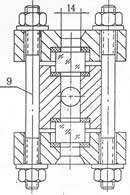

Six, appearance size chart:

3. (1) needle valve type (2) ontology gland 4. Liner 5. Glass 6. Nut 7. 8. Gasket u-bolt 9. Stud 10. The heating jacket

|

|

|

|

Seven, classification and scope of use:

1, according to the principle of work can be divided into: transmission type and reflection type two kinds, the use scope is as follows:

A, pervious to light glass level gauge is mainly used for observation of opaque or colored liquid level;

B, reflective glass level gauge is mainly used for observation of colorless, transparent liquid level;

2, according to the operating temperature can be divided into: normal and high temperature type two kinds, the specific scope is as follows:

A, ordinary glass level gauge is mainly used for pressure level is less than or equal to PN6.4 MPa, the operation of the measured medium temperature less than or equal to 250 ℃.

B type, high temperature and can be divided into: high temperature and low pressure type, high temperature and medium pressure and high temperature and high pressure, the specific scope is as follows:

1), high temperature and low pressure type glass level gauge is mainly used for pressure level is less than or equal to PN4.0 MPa, the operation of the measured medium temperature greater than 250 ℃, and less than or equal to 400 ℃.

2), high temperature and medium pressure type glass level gauge is mainly used for pressure level is less than or equal to PN6.4 MPa, the operation of the measured medium temperature greater than 250 ℃, and less than or equal to 400 ℃.

3), high temperature and high pressure type glass level gauge is mainly used for pressure level is less than or equal to PN25.0 MPa, the operation of the measured medium temperature greater than 250 ℃, and less than or equal to 400 ℃.

3, according to the grades of pressure can be divided into: low pressure type, medium pressure and high pressure three types, specific scope is as follows:

A, low voltage type glass level gauge is mainly used for pressure level is less than or equal to PN4.0 MPa, the operation of the measured medium temperature less than or equal to 250 ℃.

B, medium-pressure type glass level gauge is mainly used for pressure level is less than or equal to PN6.4 MPa, the operation of the measured medium temperature less than or equal to 250 ℃.

C, high-pressure type glass level gauge is mainly used for pressure level is less than or equal to PN25.0 MPa, the operation of the measured medium temperature less than or equal to 250 ℃.